Hyperbaric oxygen therapy provides remarkable medical and wellness benefits. It is, for example, effective in wound healing, providing relief against inflammation, improving cognitive acuity, and promoting athletic recovery, among many other conditions.

You can access HBOT treatment sessions in hospitals, specialized HBOT clinics, and even spas. However, seeking regular sessions can get expensive and facilities that have hyperbaric chambers can be few and far between in some regions. You may, as a result, find it better to build your own hyperbaric chamber.

Wondering where to begin? Read on as we delve into all it takes to build a safe defective hyperbaric chamber.

It is vital to have an in-depth understanding of hyperbaric chambers if you are going to build one. So, let’s begin by defining the design and working principles of these devices.

A hyperbaric chamber consists of two key components: a sealed chamber and a source of pressurized oxygen. The chamber shell can be made of rigid or flexible materials depending on the pressurization levels it will be used for. High-pressure units usually require rigid shell materials that can withstand the immense pressure.

The pressurized pure oxygen is delivered through a system of hoses. It is controlled and monitored using gas valves. Factors such as oxygen flow and how gradually the chamber becomes pressurized vary from one chamber to another and they can sometimes be adjusted using the settings on the control panel.

When the hyperbaric chamber is in use, the atmospheric pressure gradually increases until it reaches the prescribed level; this can range between 1.3 to 3 ATA. The increase in pressure prompts the body system to inhale and absorb higher levels of oxygen. This activates the body’s healing system and can speed up recovery from conditions like carbon monoxide poisoning, non-healing wounds, inflammation, and more.

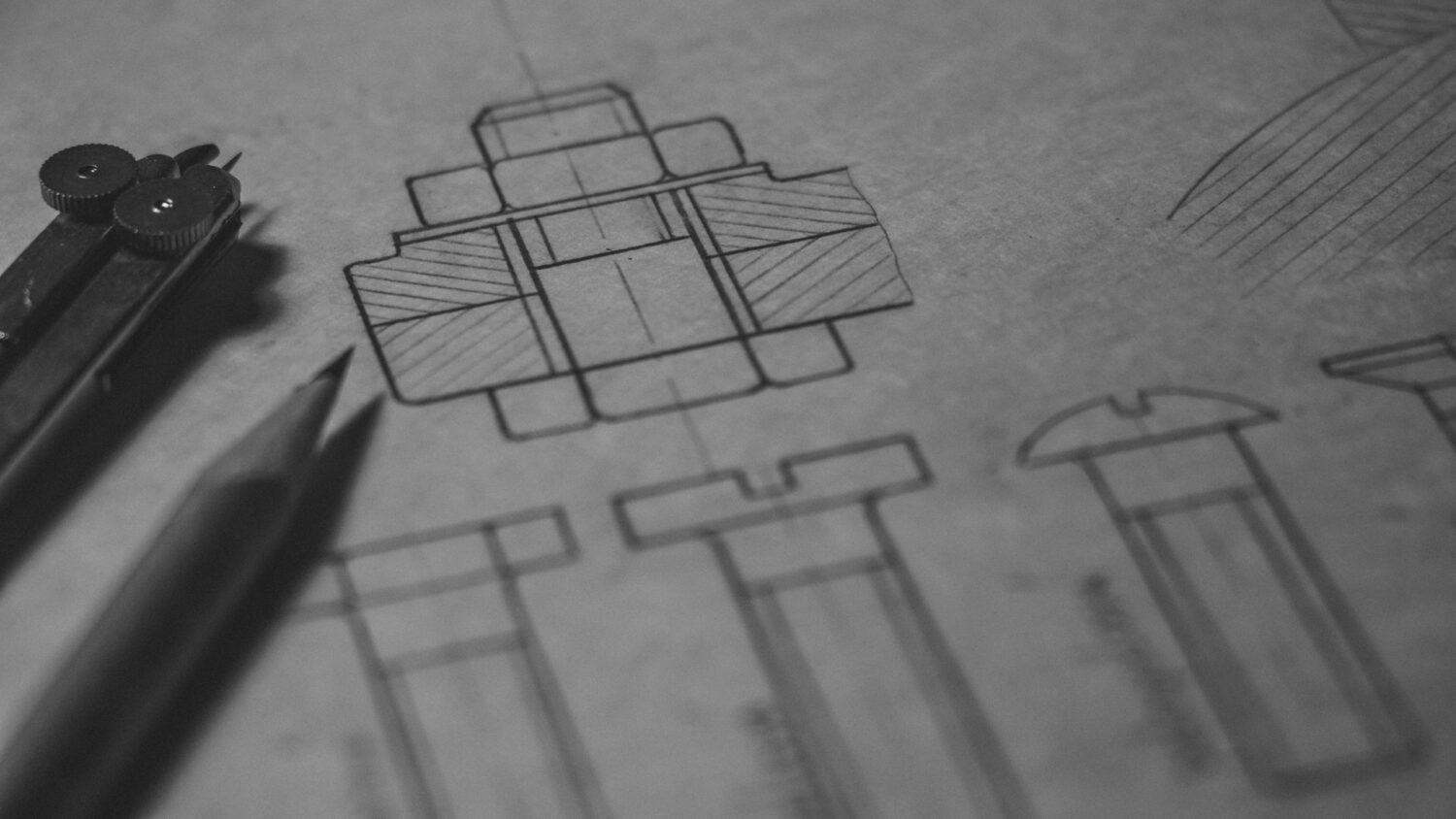

Start by creating a detailed design plan outlining:

Be sure to factor in comfort features and consider the amount of space you have when determining the dimensions of the chamber.

Building a hyperbaric chamber is a major undertaking that requires very specific materials that you should select based on the design that you come up with. A typical shopping list for such a project may comprise:

Purchase all the required materials and tools based on your design. It is advisable to ask your suppliers to customize things like the shell materials based on your design so that you only have to handle the assembly of the parts. Their high-end machinery is also likely to get you more precise dimensions and material thickness.

First, assemble the chamber frame (if your design requires one). You can then move on to assembling the shell and use the stainless steel accessories to hold all the components together

Ensure that there are no gaps or loose joints in the entire system. This is the only way you will be able to achieve the airtight conditions that a hyperbaric chamber should have.

Finally, install the pressure-resistant door and test its locking mechanism. Review the whole setup to confirm its stability and ensure that all the parts fit perfectly.

Connecting the oxygen supply system entails connecting the oxygen source to the chamber using a hose. You may have to drill a small hole in the chamber to insert the hose but if you had your chamber material customized, the openings should already be in place.

Install the right gauges to enable you to control and monitor pressure levels once the hose is in place. You can then test the oxygen supply system as a whole to ensure that it works properly and that there are no leaks. Keep in mind that pure oxygen can accelerate a fire so be careful as you navigate both installation and testing.

The ventilation system of a hyperbaric chamber helps maintain an optimal temperature in the chamber by maintaining a balanced flow of air in and out of the chamber. It also prevents carbon dioxide from building up in the chamber during treatment sessions.

The system includes accessories like filters, fans, or air ducts. They, however, should be carefully installed to ensure that they can not upset the hyperbaric balance in the chamber when it is running.

Hyperbaric chamber safety features are non-negotiable as they can be the thin line between safety and harm or life and death. So, while safety options abound, ensure that you at least install both an emergency pressure release valve and a pressure gauge to monitor the pressure levels inside the chamber.

Include comfortable seating or bed provisions to offer comfort during hyperbaric therapy treatment sessions. Some ambient lighting can equally make sessions more calming, less claustrophobic, and allow chamber users to read if they like.

Completing the hyperbaric chamber construction process is a major hurdle but hold off from using it until you have it rigorously tested and certified as safe to use. The key steps involved in this phase include:

These tests evaluate whether the hyperbaric chamber you have built can safely withstand pressure when it is put to work. They also measure whether the chamber maintains the right pressure levels throughout a session. This is to ensure that it will offer effective therapy and not expose users to risks like barotrauma.

Other safety measures like emergency depressurization and fire safety are also examined.

Once your hyperbaric chamber is tested, the experts or regulatory body that performed the tests will give you feedback as to whether it meets the required safety standards and industry guidelines. Such feedback can range from getting express certification, your hyperbaric chamber being deemed unfit for use, or a list of recommendations outlining the improvements that you should make.

You may need to make some modifications or design alterations depending on the kind of feedback you received from the testing phase. Strive to follow the recommendations to the letter as this is likely to make your hyperbaric chamber safer and more efficient. Proceed to have it reevaluated after you make the changes and obtain the necessary certification.

Even the safest hyperbaric chamber can quickly become a safety risk if it is not used the right way. It is, therefore, vital to establish proper usage protocols and ensure that all users know and understand them. Consider:

Endeavor to provide adequate training to everyone that will use or be within the vicinity of the hyperbaric chamber. They should understand:

Create a maintenance schedule so that you can identify and resolve any issues before they progress. It could feature checks like chamber inspections and calibration of gauges and valves.

Further, consider that germs in a hyperbaric chamber can result in infections because users are likely to inhale them during hyperbaric therapy sessions. Regular chamber cleaning is thus worth investing in and should be supported by users adhering to high hygiene practices during their therapy sessions.

Keeping a record of user vitals before and after treatment, seeking feedback about their experiences, and the hyperbaric conditions during their treatments can help you maintain optimal safety standards. It can also tell you just how effective your hyperbaric chamber is.

For some insightful reads, we’ve curated a list of recommended articles just for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Ultimately, building a hyperbaric chamber takes time, requires a significant financial investment, and a willingness to work through the regulations surrounding hyperbaric devices. Still, if you stay committed to the course, pulling off this big feat can be highly rewarding and can earn you a custom hyperbaric chamber that suits your needs just right.

Get in touch with us and unlock your full well-being potential!

The OxygenArk team is here to assist you every step of the way.